In the 10,000+ watt era, How to Choose a High Power Laser Cutting Machine -- 12KW VS 20KW Performance Competition

Release time:

2022-05-11

Author:

Source:

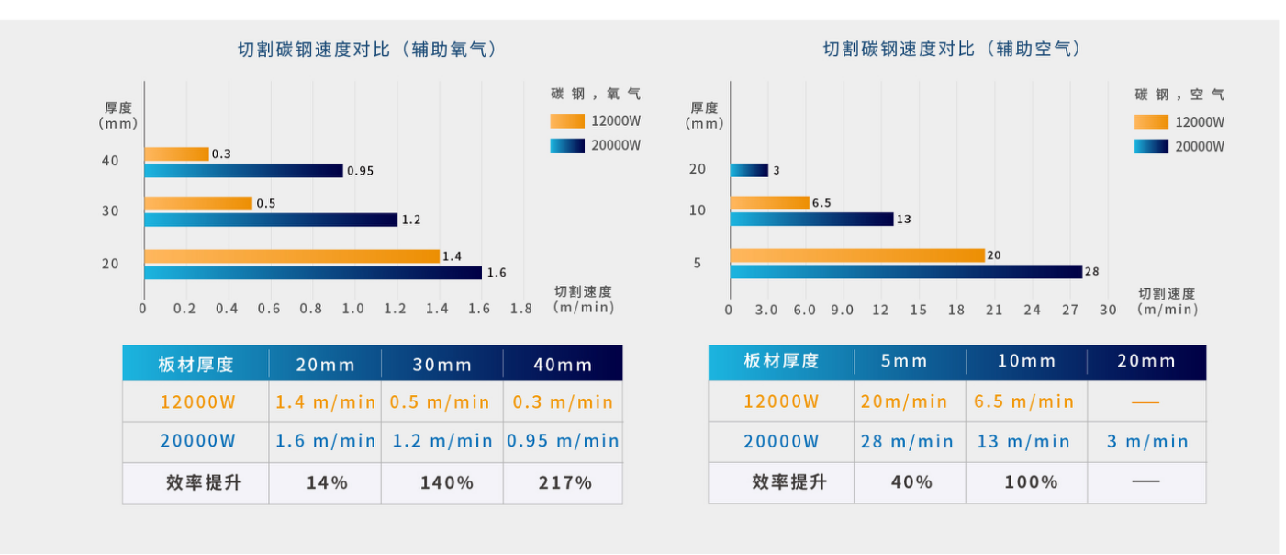

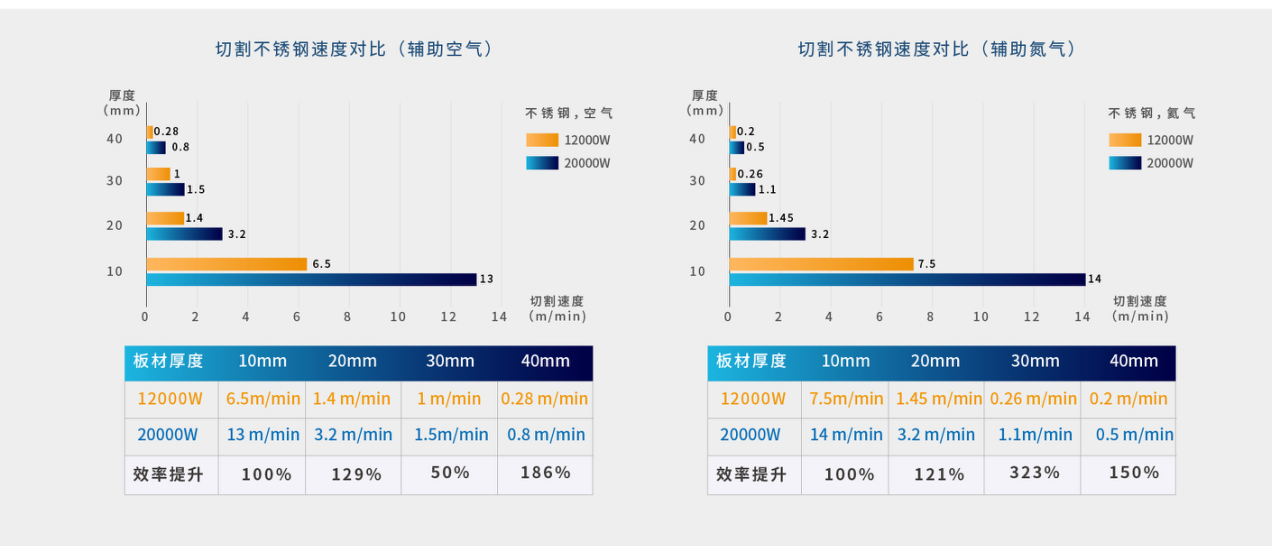

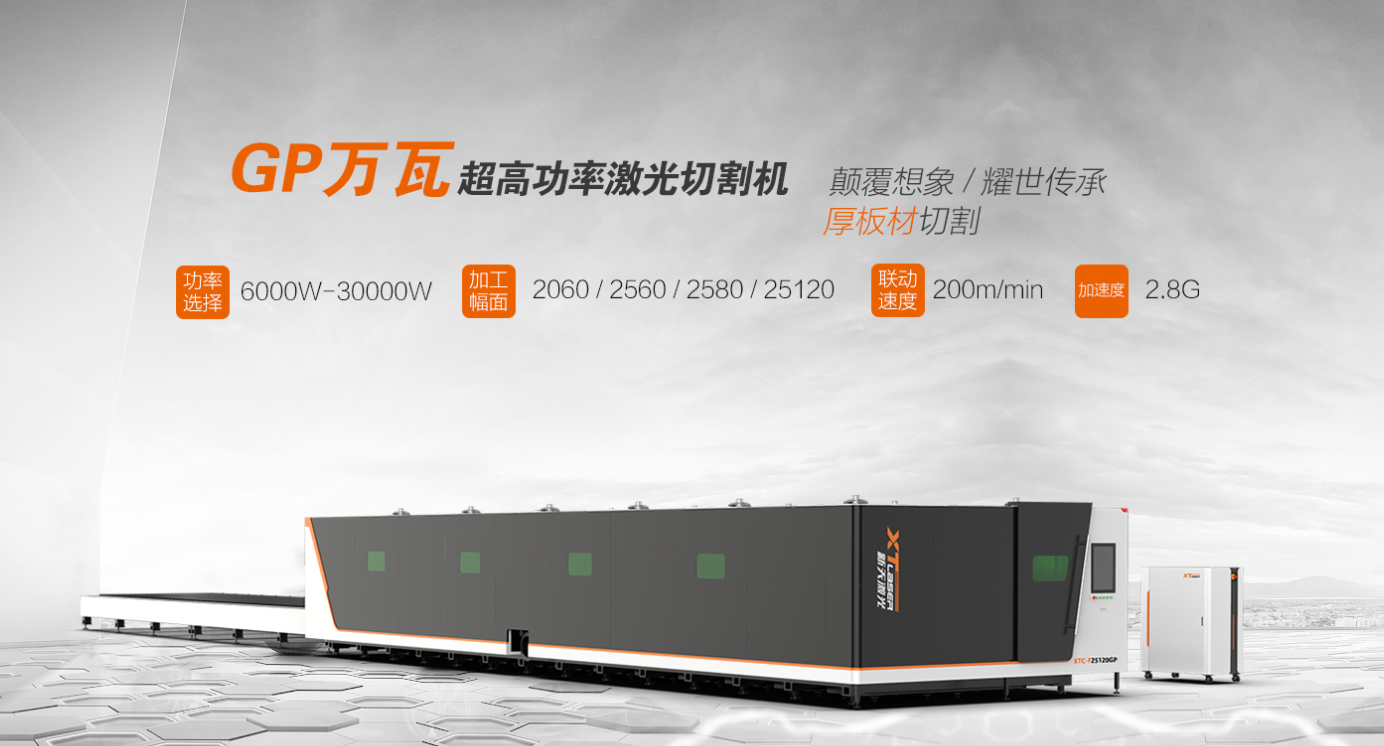

With the pursuit of efficiency and craftsmanship in the entire processing and manufacturing industry, domestic laser cutting technology has continued to make breakthroughs, and the 10,000-watt laser cutting machine has been enthusiastically sought after by the entire industry due to its unique advantages such as high power, high performance, and high stability. The era of the 10,000-watt laser cutting machine has come. With 10,000 watts, it leads the future.

Key words:

Previous Page

Address: No. 866 Chunyuan Road, Gaoxin East District, Jinan City, Shandong Province,China

Business License

Powered by www.300.cn Friendly link: xtfiberlaser